Company Overview

Founded in 2011 and located in New Hampshire, Solid Machine specializes in precision CNC turning and 5-axis milling of rotating bladed turbomachinery hardware for aerospace, automotive, defense, energy, oil & gas, and industrial applications. We also offer precision machining of components in specialty composite alloys.

Our talented team has over 6 decades of experience in the machining of rotating bladed turbomachinery hardware in a wide range of materials to the tightest dimensions and most stringent specifications. We are more than a “chip cutter” and can suggest more efficient manufacturing methods, processes, and design changes that will meet your needs, while lowering your production costs.

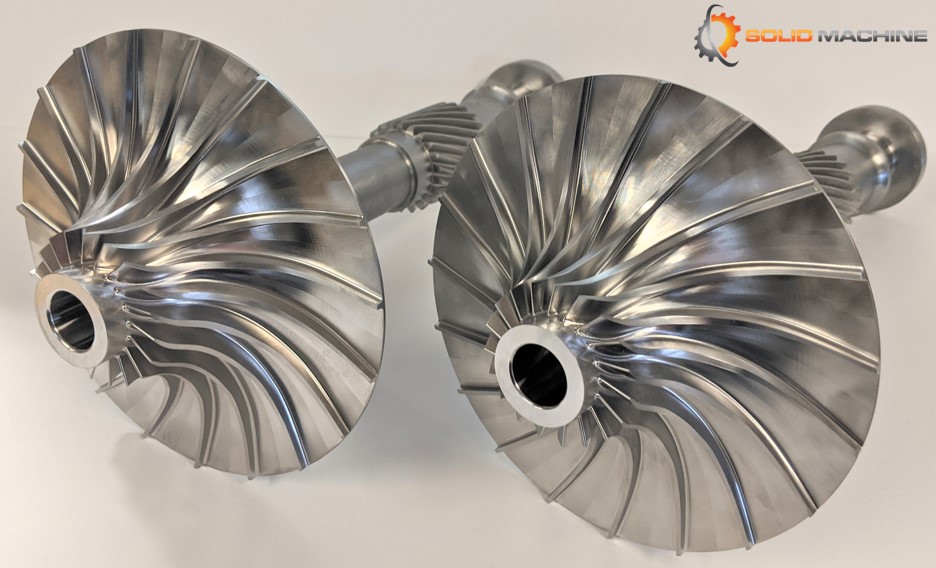

We manufacture over 45,000 parts per month including turbocharger impellers, aero-engine spacers, axial and radial impellers, turbines, compressors, blades/vanes, and custom hardware up to Ø650mm.

Our Goal is Simple: Technical Perfection

Solid Machine is known for three things: exceptional engineering, superior processes, & outstanding machining. Our roots are deeply tied to the automotive and aerospace industries, and our drive for perfect engineering, processes, and machining stems from that. When you’re building something upon which lives will depend, there is no margin for error. Not every manufacturer will hold razor thin tolerance levels. Not every manufacturer will personally oversee the development and machining of every part that comes off the line. We’re not every manufacturer.

State of the Art in Every Way

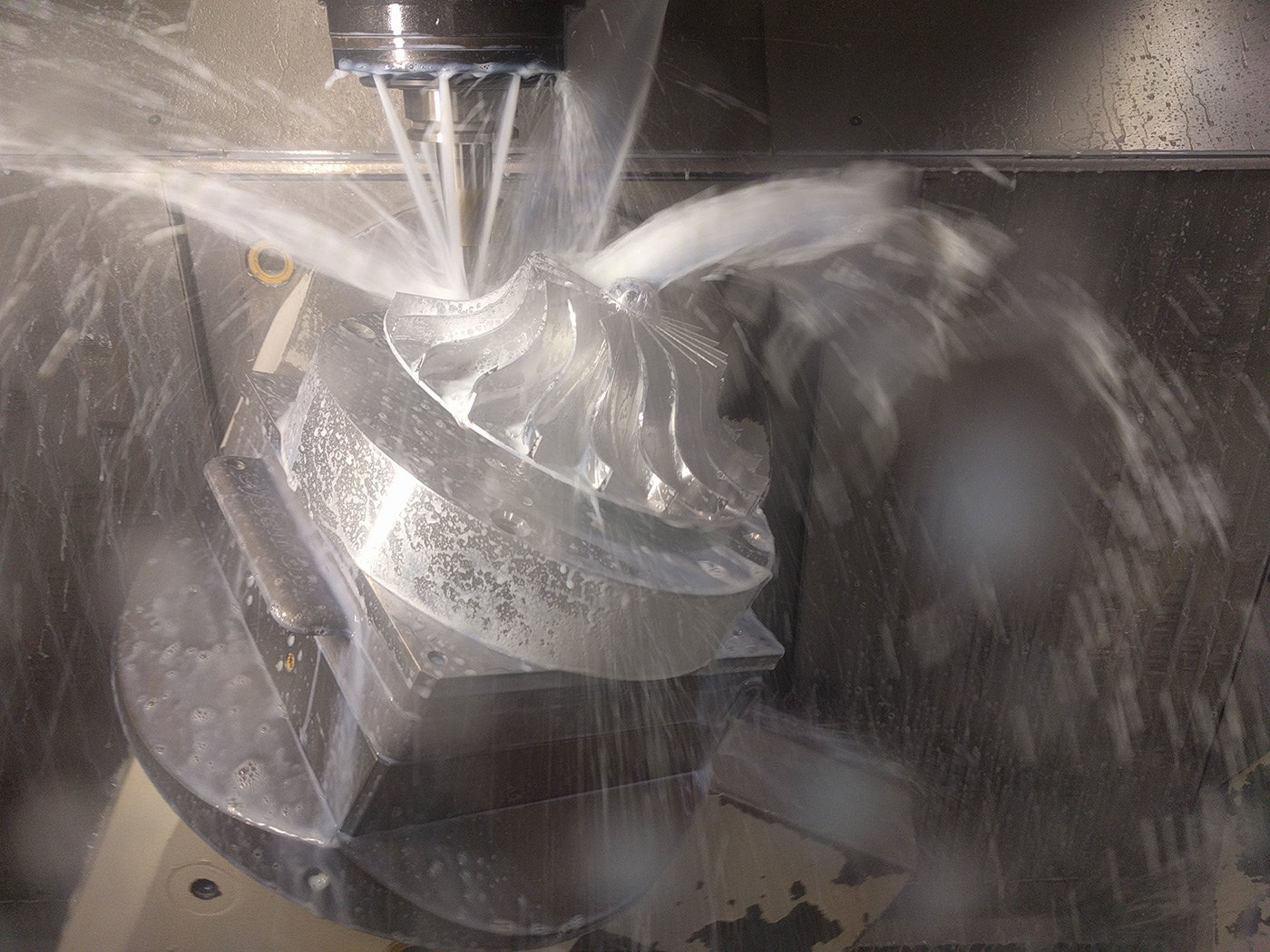

Our simultaneous 5-axis machining centers allow us to manufacture an extensive array of complex components and one of our key strengths is the ability to confidently satisfy our client’s needs for one-off prototypes or production (whether high-mix low-volume to low-mix mass production).

We push the boundaries of manufacturing and challenge the status quo by constantly looking for new ways to use, develop or evolve existing processes. We leverage sophisticated machine tool technologies to supply parts of the highest quality. We engineer total process control and believe that better engineering builds better components. It’s just that simple.

A Reputation You Can Count On

We don’t settle for anything less than perfection. And we don’t say that lightly. As a key manufacturer for many OEM suppliers, we know that it’s not just about the quality of the part we provide, it’s our ability to get the right product out the door at the right time. We’re committed to providing our OEM customers with the exacting attention to detail you’ve come to expect from Solid Machine. We don’t expect anything less. Neither should you.

Being an OEM supplier means that we’re putting more than just our reputation on the line, we’re putting yours out there as well. We understand that risk and know what it takes to build a high-quality relationship in addition to a high-quality product. By working closely with you we build a partnership throughout the entirety of the project from design to engineering and final execution. This partnership based on trust, integrity and competence is what gives our customers the end results they want and need.

Solid Machine | 61 Airport Dr.- Unit 1 | Rochester, New Hampshire 03867

Phone: (603) 332-5511 | E-mail: info@solidmachinenh.com