SUMMARY

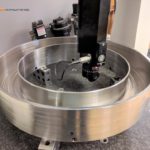

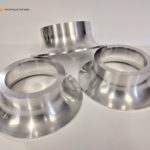

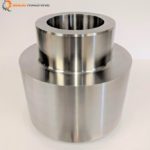

Solid Machine performs precision CNC turning on well over 40,000 parts per month including turbocharger impellers, compressor impellers, shafts, shrouds, sleeves, diffusers, bearing cartridges, bushings, spacers, housings, volutes, turbine rotors, pumps, and custom hardware up to Ø28.0” (710mm).

Whether you need a complex prototype or high-volume production, contact us to experience the difference Solid Machine can make in bringing your product or vision to life.

SHOWCASE

We hope the following gallery provides a glimpse at the diversity, quality and workmanship of our CNC turning capabilities.

SOLUTIONS & SPECIFICATIONS

| Max Diameter: | 28.0” (710mm) |

| Max Length: | 18.0” (450mm) |

| Max Weight: | 2,000 lbs (910 kg) |

| Materials: |

|

| Tolerances: | +/- 0.0001” to 0.0002” depending on the feature, alloy, etc. |

| Turning Capabilities: |

|

| Add’l Internal Capabilities: |

|

| Subcontracted Services: |

|

| Lead Time: | Quoted on a job by job basis, but typically under 4 to 6 weeks ARO. |

| Software: |

|

| File Formats: | We have yet to receive a model or drawing file we could not open. Try us…we’ve got you covered. |

Solid Machine | 61 Airport Dr.- Unit 1 | Rochester, New Hampshire 03867

Phone: (603) 332-5511 | E-mail: info@solidmachinenh.com